Thought Leadership

Shifting The Focus: From Cost Per Batch to Cost Per Gram in Biologics Manufacturing

Cost efficiency is a key factor in selecting a CDMO for biologics manufacturing. Cost per batch has been used as a metric for cost analysis for many years. While this metric accounts for all expenses in producing a single batch, it lacks the precision needed to pinpoint inefficiencies in the process and specific areas for cost reduction. The industry is now shifting towards a more detailed understanding of costs, making process efficiency and innovation very crucial.

Cost efficiency is a key factor in selecting a CDMO for biologics manufacturing. Cost per batch has been used as a metric for cost analysis for many years. While this metric accounts for all expenses in producing a single batch, it lacks the precision needed to pinpoint inefficiencies in the process and specific areas for cost reduction. The industry is now shifting towards a more detailed understanding of costs, making process efficiency and innovation very crucial.

Cost per gram refers to the production cost for one gram of a biologic substance. This transition from cost per batch to cost per gram relies on adopting innovative technologies in manufacturing.

At Enzene, we believe this shift requires a fundamental rethinking of production processes, optimization, sustainability, and technology integration. Biotech companies value cost per gram the most, as they strive for maximum process efficiency and optimal spending, which are critical for their survival.

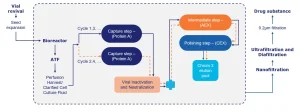

With our fully-connected continuous manufacturing™ platform, single-use systems, automation, PAT, and green chemistry initiatives, we aim to implement this shift and drive the adoption of this model within the industry.

EnzeneX™: Our fully-connected continuous manufacturing™ (FCCM™) Platform

Our ultimate goal is to deliver life-saving therapies to patients more effectively and affordably while providing smaller biotech’s with increased access to efficient manufacturing.

To learn more about our fully-connected continuous manufacturing™ platform contact us or find out more.

Latest from Enzene

Join the revolution

Fueled by our continuous innovation and armed with EnzeneX™, our fully-integrated CDMO solutions and our biosimilars pipeline are designed to help bring your biologics innovations to life.